Lathes are powerful machines that are used for shaping and cutting materials such as metal, wood, and plastic. However, like any machine, they can sometimes experience problems and make strange noises. If your lathe is making strange noises, there are a few things you can do to troubleshoot the problem and get it running smoothly again.

Identify the source

The first step is to identify the source of the noise. Is it coming from the motor, the spindle, or the belt? Is it a high-pitched squeal or a low-pitched growl? Knowing the source of the noise will help you narrow down the potential causes and make it easier to troubleshoot the problem.

Check the motor of your lathe

If the noise is coming from the motor, it could be caused by a problem with the bearings. Bearings are the small metal balls or rollers that help the motor spin smoothly. Over time, these bearings can wear out and start to make noise. To check for this, you can remove the belt and spin the motor by hand. If the noise persists, it’s likely that the bearings need to be replaced.

Check the spindle of your lathe

If the noise is coming from the spindle, it could be caused by a problem with the chuck. The chuck is the part of the lathe that holds the workpiece in place. If the chuck is loose or damaged, it can cause the workpiece to wobble and make noise. To check for this, you can try tightening the chuck or replacing it if it is damaged.

Check the belt of your lathe

If the noise is coming from the belt, it could be caused by a problem with the belt tension. If the belt is too loose, it can slip and make noise. To check for this, you can use a belt tension gauge to measure the tension of the belt. If the belt is too loose, you can adjust the tension to bring it back to the proper level.

Other reasons why your lathe is making strange noises

Another potential cause of strange noises in a lathe is a problem with the lubrication. Lathes need to be lubricated regularly to keep the moving parts running smoothly. If the lubrication is low or dirty, it can cause friction and make noise. To check for this, you can check the oil levels and clean or replace the oil as needed.

If you are unsure of the problem or unable to fix it, it’s best to consult the manual of your lathe or contact the manufacturer for technical support. It’s also a good idea to have the lathe serviced by a professional to ensure that it is running at peak performance.

Preventing your lathe from causing problems

To prevent strange noises in the future, it’s important to maintain your lathe regularly. This includes regular cleaning, oil changes, and checking for worn or damaged parts. It’s also a good idea to use high-quality tools and materials to reduce wear and tear on the lathe.

In conclusion, if your lathe is making strange noises, there are a few things you can do to troubleshoot the problem and get it running smoothly again. Identifying the source of the noise, checking for worn or damaged parts, and maintaining the lathe regularly are key steps to preventing and fixing strange noises. If you are unsure of the problem or unable to fix it, it’s best to consult the manual of your lathe or contact the manufacturer for technical support. And also be aware of the safety precautions when working with lathe.

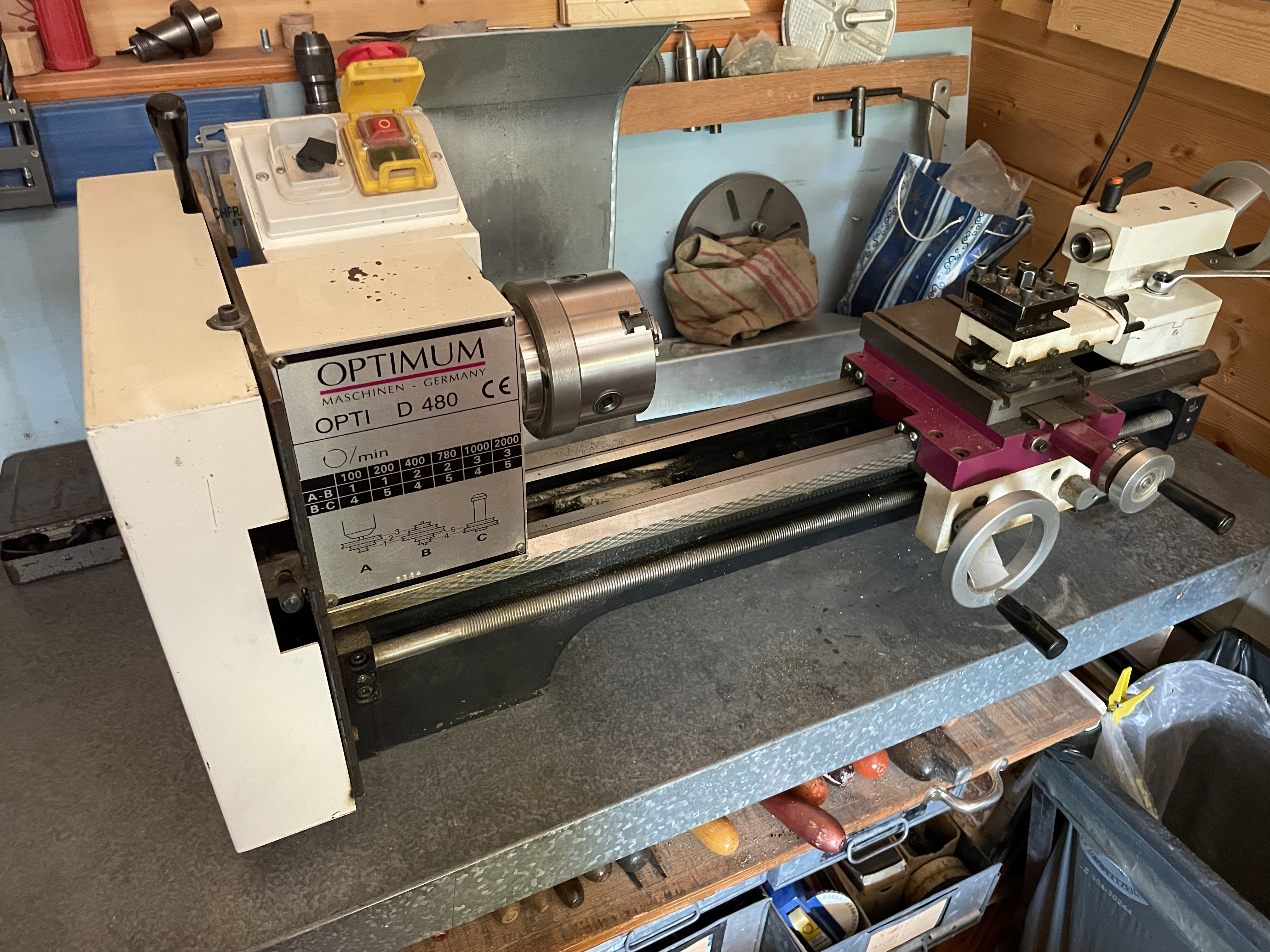

A small overview of lathe manufacturers

There are a lot of companys, which are producing lathes in many different performance categories. Here is a small overview:

- Haas Automation

- Okuma

- Mazak

- DMG MORI

- Doosan Machine Tools

- Hurco

- Johnford

- Tsugami

- Mori Seiki

- YCM

These manufacturers offer a wide range of lathes, including manual lathes, CNC lathes, and high-precision lathes. Prices can vary greatly depending on the model and features, with some entry-level manual lathes starting at around $5,000 and high-end CNC lathes costing over $100,000.

It’s important to consider your specific needs and budget when choosing a lathe. If you are a hobbyist or small shop, a manual or entry-level CNC lathe may be sufficient. However, if you are a larger shop or need high precision, a more advanced CNC lathe may be necessary.

It’s also a good idea to research and compare the features and specifications of different models before making a decision. Some features to consider include the size and capacity of the lathe, the type of control (manual or CNC), the speed range, and the accuracy and repeatability. Additionally, you should also consider the cost of the tooling, accessories and maintenance before making a decision.

It’s recommended to visit the websites of the manufacturers or visit the trade shows to see the machines in action, ask for demonstrations and also request for quotes. This will give you a better understanding of the capabilities and the prices of the different models available in the market.